In today’s rapidly evolving industrial environment, meeting increasingly stringent environmental regulations is more critical than ever. Regenerative Thermal Oxidizers (RTOs) are among the most effective solutions for air pollution control. These systems are primarily used to treat volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other industrial emissions that can harm the environment. As industries face increasing pressure to minimize their environmental impact, adopting RTO systems is no longer just an option, but a key factor in maintaining compliance and efficient operations.

In this article, we’ll delve into how RTO systems work, their benefits, and the industries that rely on them. Whether you’re in the chemical, automotive, or food processing industries, understanding how RTOs can streamline your operations and reduce emissions will help you make more informed decisions.

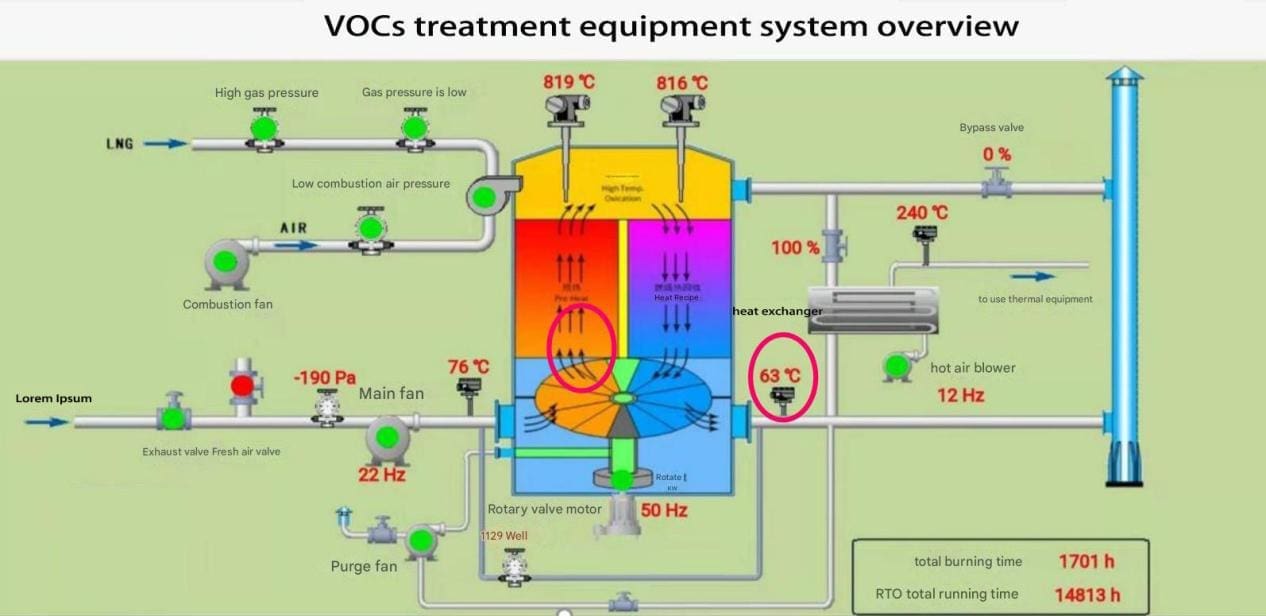

How RTOs Work: The Technology Behind Their Efficiency

- Pollution Air Intake: Polluted air from industrial processes is drawn into the RTO system through a series of ducts.

- Regeneration Process:Air flows through a ceramic bed preheated by the previously emitted exhaust gas, effectively reducing the amount of fuel required to reach the desired temperature.

- Thermal Oxidation:The preheated air is heated to high temperatures (typically between 800°C and 1200°C) in the combustion chamber. This high temperature decomposes VOCs into carbon dioxide and water vapor—harmless byproducts.

- Heat Recovery:The RTO system uses the heat generated during the oxidation process to preheat the incoming polluted air. This regeneration process maximizes the system’s energy efficiency and minimizes fuel consumption.

Applications of Regenerative Thermal Oxidizers

- Chemical Manufacturing: The chemical manufacturing industry typically uses solvents and chemicals that release volatile organic compounds (VOCs). These emissions can be harmful to the environment and worker health. RTO helps significantly reduce these emissions, ensuring compliance with environmental regulations such as U.S. Environmental Protection Agency (EPA) standards and local air quality regulations.

- Automotive Manufacturing: During automotive production, painting and coating processes release significant amounts of VOCs. By installing a Real-Time Pollutant Treatment (RTO) system, automotive plants can significantly reduce emissions and minimize the environmental impact of their operations. This is especially important for companies that want to meet both U.S. Environmental Protection Agency (EPA) regulations and global sustainability standards.

- Food Processing: Food processing plants use various chemical treatments, packaging materials, and cooking processes, all of which release volatile organic compounds (VOCs) and odors. RTO (Responsible Toll Collection) systems can treat these emissions, ensuring the plant operates within regulatory limits while reducing odors that may affect surrounding communities.

- Pharmaceuticals: Pharmaceutical manufacturing facilities rely on RTOs to treat emissions generated during their production processes. These facilities often use solvents in drug production, which leads to the generation of harmful air pollutants. RTOs help ensure these pollutants are effectively removed before being released into the atmosphere.

- Paints and Coatings: The paint and coatings industry is another significant user of RTOs because it generates VOCs and harmful air pollutants (HAPs) during production and application. RTOs help reduce these harmful emissions, ensuring manufacturers comply with environmental regulations and safety standards.

Environmental and Economic Benefits of Regenerative Thermal Oxidizers (RTOs)

One of the key advantages of RTOs is their ability to deliver both environmental and economic benefits. Specifically:

- Environmental Compliance: RTO systems help businesses comply with stringent air quality standards set by regulatory agencies such as the U.S. Environmental Protection Agency (EPA) and European Union regulations. By reducing emissions of volatile organic compounds (VOCs) and other pollutants, businesses can avoid hefty fines and contribute to improved air quality.

- Energy Efficiency: RTOs can recover up to 97% of the heat generated during the oxidation process. This significantly reduces energy costs compared to traditional thermal oxidizers without heat recovery capabilities.

- Reduced Operating Costs: The energy savings from using an RTO system make it a cost-effective solution for long-term air pollution control. By recovering heat, RTOs reduce the need for additional fuel, thereby lowering overall energy consumption.

- Sustainability: Investing in an RTO aligns with a company’s sustainability goals. Companies using RTO systems demonstrate their commitment to reducing their environmental footprint while complying with environmental regulations.

Customer Testimonials

“After installing the RTO system at our chemical plant, we successfully met the new regulations of the U.S. Environmental Protection Agency (EPA). At the same time, energy costs have also decreased significantly.” — John, Environmental Compliance Officer, a U.S. chemical plant

“We have been using RTO technology at our automotive plant in Germany for over two years. The reduction in emissions is very significant, and the system operates smoothly with almost no maintenance.” — Anna, Production Manager, a German automotive plant